- Home

- Our Products

- Orthopedic Instruments

- RETRACTORS

- Bone Files Rasps

- DOINL NOINGLOUSIVIDDLEAS

- COIVIFAESSIOMDICTNATN rUNCLTS

- RIB 3HEARS

- NID SПЕAUC CIENIVOIVI CNISEL

- 3PREADER3

- DOINL AUINOLOuC IVIDDLLAJ

- LLLVAIOUS

- BONE HOLDING FORCEРЗ

- PELVIC REDOCTIONN3TROIVIENT3

- BONE GRASPER3IVIENI3C03 CLAIVIP3

- DOINE IVIALLLIS

- DUINE CURETITC

- ELEVATORS

- DUINE HOLDINO runcErJ

- CANTILAOLACOSION FUNCLS

- BONE COTTING FORCEPS

- DOINE COTN TURCEPS

- FLAIL DLIVUENS

- Services

- Blogs

- About Teton

- Contact us

- 3PREADER3

- BONE COTTING FORCEPS

- Bone Files Rasps

- BONE GRASPER3IVIENI3C03 CLAIVIP3

- BONE HOLDING FORCEРЗ

- BONE RONGEOR3IBBLER3

- CANTILAOLACOSION FUNCLS

- CHISELS- GOUGES-OSTEOTOMES

- COIVIFAESSIOMDICTNATN rUNCLTS

- Dental Instruments

- DOINE COTN TURCEPS

- DOINE IVIALLLIS

- DOINL AUINOLOuC IVIDDLLAJ

- DOINL NOINGLOUSIVIDDLEAS

- DONL CORETTES

- DUINE CURETITC

- DUINE HOLDINO runcErJ

- ELEVATORS

- FLAIL DLIVUENS

- Gynecology Instruments

- LLLVAIOUS

- NID SПЕAUC CIENIVOIVI CNISEL

- Orthopedic Implants

- Orthopedic Instruments

- Arthroscopy

- Bone Curettes

- Bone Cutters

- Bone Holding Forceps

- Bone Hooks

- Bone Nibblers

- Bone Rasps

- Bone Spreaders

- Dissectors

- Elevators

- Hip Joint Instruments

- Hip Retractors

- Hip Revision Instruments

- Locking Pliers

- Mallets

- Measuring Instruments

- Misc

- Miscellaneous

- Orthopedic Dressing Instruments

- Orthopedic Kits

- Osteotomes

- Osteotomes & Gouges

- Pelvic Reduction Instruments

- Pin Introducers

- Pliers & Wire Cutters

- Reamers & Awls

- Retractors

- Screwdrivers

- PELVIC REDOCTIONN3TROIVIENT3

- RETRACTORS

- RIB 3HEARS

- Spinal Implants

- Spinal instruments

- Surgical Instruments

- Uncategorized

- Veterinary implants

- Veterinary Instruments

How We Make It

Explore Teton Surgical Manufacturing Process

Raw Material

All our raw material is supplied by the top-quality providers in China. Besides the raw material certificates provided by the supplier, we test every patch of the raw material by chemical and physical test and keep samples records for tracing which make sure the raw material safety.

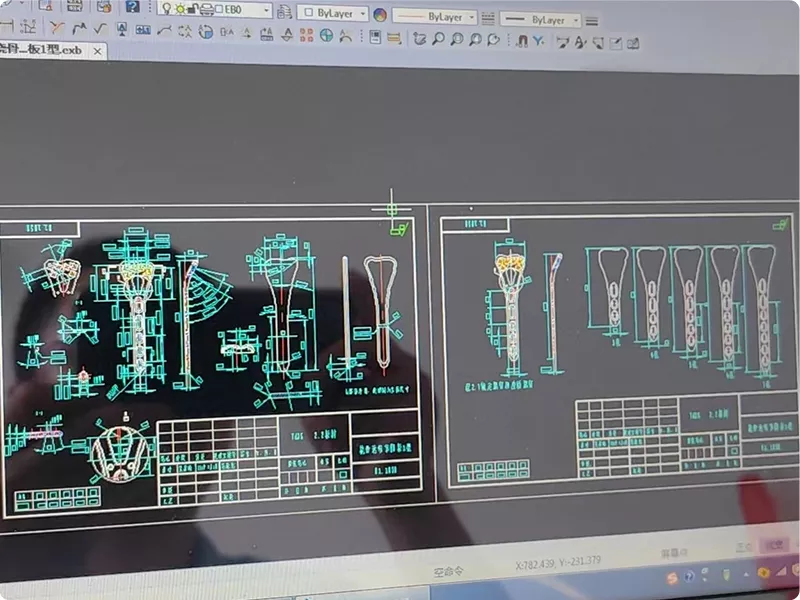

Product Design

We have our own design team who analyses and learn from the international brands and collaborate with our technical team to test and improve the design of the products. The surgeons and clinical history provide the trustworthy feedbacks for the improvements of the designs.

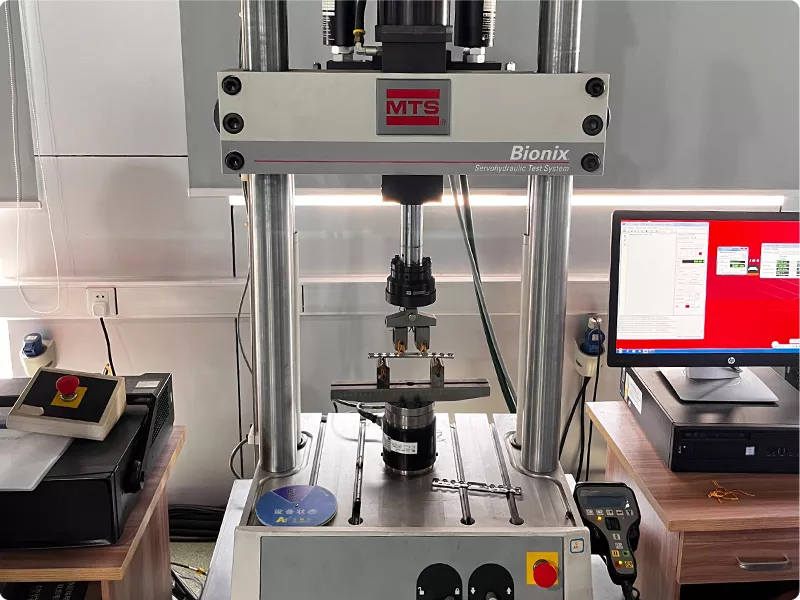

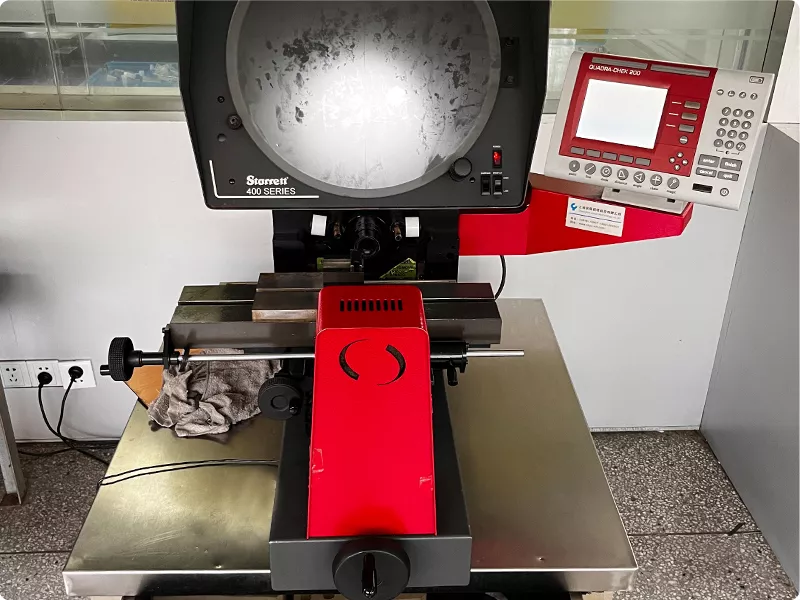

Mechanical Test

We established our own mechanical testing lab which do the latest test methods with advanced equipment. Our extensive testing covers static, fatigue, torsion and wear testing.

Production

We have 20 HASS CNC machines, 5 Bridgeport CNC machines, 5 Brother CNC machines, 43 Star CNC machines and all products are produced according to the highest production standards by these advanced machines. Our quality control team conduct inspections after every production procedure from start to finish. This is the only way to make sure every process can be accurate to the finished products.

Polishing

We established a good environment friendly place for our polishing team who polish the products surface strictly according to the work standards.

Washing

After rough washing and fine washing by microwave washer to remove all the dirty.

Surface Treatment

After All our products undergo intensive surface treatment to ensure top levels of hygiene and texture. Our color anodizing process are accord with the environment protection regulations.

Final Products Inspection

All the products will be checked and do the printing after the QC test.

Packaging

We established clean room which to package the products. We can meet the requirements of the sterile non-sterile packaging and sealed.