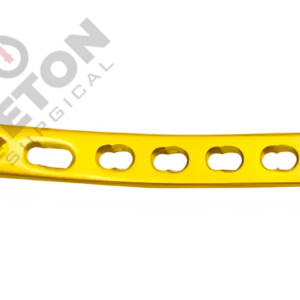

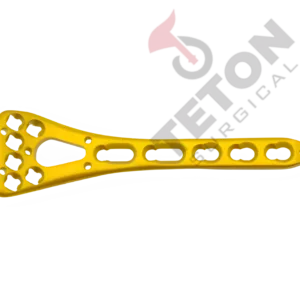

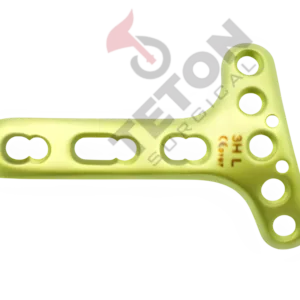

The Proximal Medial Tibial Locking Plate is designed to offer rigid fixation for medial tibial plateau fractures, metaphyseal fractures, and osteotomy procedures involving the proximal tibia. Its anatomically contoured shape ensures a precise fit to the medial side of the tibia, reducing the need for intraoperative bending and minimizing soft tissue irritation.

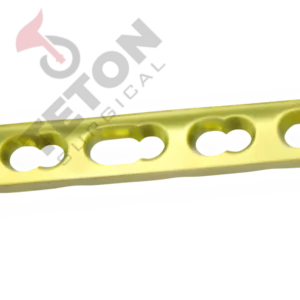

Manufactured from high-grade surgical stainless steel, the plate features a 4.2mm thickness and 13mm width, providing a balance between strength and low profile. Compatible with 3.5mm Locking Screws and 3.5mm Cortical Screws, this plate is ideal for both primary fixation and complex reconstructive surgeries where angular stability is crucial.

Technical Features & Specifications:

-

Material: Surgical-Grade Stainless Steel (Biocompatible and corrosion-resistant)

-

Screw Compatibility: 3.5mm Locking Screws & 3.5mm Cortical Screws

-

Plate Thickness: 4.2mm (Optimal strength without bulkiness)

-

Plate Width: 13mm (Anatomically optimized for medial tibia)

-

Surface Finish: Mirror-polished to minimize tissue irritation

-

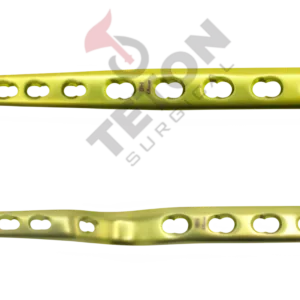

Hole Configurations: 4, 6, 8, 10, 12 Holes (Left & Right variants)

-

Available Lengths: From 83mm to 187mm

Clinical Applications & Uses:

-

Ideal for medial tibial plateau fractures.

-

Applicable for osteotomy fixation in high tibial osteotomy (HTO) procedures.

-

Ensures stable fixation in osteoporotic bones and comminuted fractures.

-

Suitable for primary fracture fixation and revision surgeries.

-

Provides angular stability to maintain fracture alignment during healing.

Advantages & Benefits:

-

Anatomically Pre-Contoured Design: Eliminates intraoperative contouring, ensuring quicker surgical procedures.

-

Locking Mechanism for Angular Stability: Prevents loss of reduction in compromised bone conditions.

-

Low-Profile Geometry: Minimizes implant prominence, reducing post-surgical discomfort.

-

Durable Material Strength: Made from premium stainless steel for long-term reliability.

-

Versatile Screw Compatibility: Compatible with widely used 3.5mm locking and cortical screw systems.

Available Configurations & Sizes:

| Side | Holes | Thickness | Width | Length |

|---|---|---|---|---|

| Left | 4 Holes | 4.2mm | 13mm | 83mm |

| Left | 6 Holes | 4.2mm | 13mm | 109mm |

| Left | 8 Holes | 4.2mm | 13mm | 135mm |

| Left | 10 Holes | 4.2mm | 13mm | 161mm |

| Left | 12 Holes | 4.2mm | 13mm | 187mm |

| Right | 4 Holes | 4.2mm | 13mm | 83mm |

| Right | 6 Holes | 4.2mm | 13mm | 109mm |

| Right | 8 Holes | 4.2mm | 13mm | 135mm |

| Right | 10 Holes | 4.2mm | 13mm | 161mm |

| Right | 12 Holes | 4.2mm | 13mm | 187mm |

Why Choose Us?

At Strength Industries, we specialize in delivering orthopedic implants that prioritize surgeon ease, clinical precision, and patient comfort. The Proximal Medial Tibial Locking Plate is a testament to our focus on high-quality materials, advanced design, and biomechanical excellence.

-

Perfect Anatomical Conformity: Designed to match the natural curvature of the medial tibia for flawless fit.

-

Rigid Fixation with Angular Stability: Ensures fracture stability even in osteoporotic conditions.

-

Minimized Soft Tissue Irritation: Low-profile design enhances postoperative patient outcomes.

-

Globally Trusted: Preferred by leading orthopedic professionals worldwide.

-

Certified Manufacturing Excellence: Adhering to stringent international quality control standards.

Choose Strength Industries for orthopedic implants that deliver clinical success and surgical confidence.

Reviews

There are no reviews yet.